Fascination About Roar Solutions

Fascination About Roar Solutions

Blog Article

Examine This Report on Roar Solutions

Table of ContentsThe Of Roar SolutionsThe smart Trick of Roar Solutions That Nobody is DiscussingAbout Roar SolutionsThe Facts About Roar Solutions Revealed

The tools register is an extensive database of devices documents that consists of a minimum collection of fields to identify each thing's location, technological criteria, Ex category, age, and ecological information. This info is essential for monitoring and managing the tools efficiently within unsafe areas. On the other hand, for periodic or RBI sampling examinations, the grade will certainly be a mix of In-depth and Close evaluations. The proportion of Comprehensive to Close examinations will be established by the Equipment Risk, which is examined based upon ignition danger (the probability of a resource of ignition versus the possibility of a combustible ambience )and the unsafe location classification( Zone 0, 1, or 2). This variation will also affect the resourcing needs for job prep work. As soon as Whole lots are specified, you can create tasting plans based on the example size of each Great deal, which describes the number of random devices products to be inspected. To identify the called for example size, 2 elements require to be evaluated: the dimension of the Great deal and the group of examination, which shows the degree of initiative that should be used( decreased, normal, or increased )to the evaluation of the Great deal. By incorporating the classification of evaluation with the Lot size, you can then develop the proper rejection requirements for a sample, meaning the allowed variety of malfunctioning things discovered within that example. For more details on this process, please refer to the Power Institute Standards. The IEC 60079 typical recommends that the maximum period in between assessments should not surpass three years. EEHA evaluations will certainly likewise be conducted beyond RBI campaigns as component of set up maintenance and tools overhauls or repairs. These inspections can be attributed towards the RBI example sizes within the influenced Lots. EEHA assessments are conducted to identify faults in electric tools. A heavy racking up system is crucial, as a solitary tool might have multiple mistakes, each with varying levels of ignition risk. If the consolidated score of both inspections is less than two times the mistake rating, the Great deal is considered appropriate. If the Great deal is still taken into consideration inappropriate, it should undergo a full inspection or validation, which might set off more stringent inspection procedures. Accepted Whole lot: The reasons of any kind of mistakes are recognized. If an usual failing setting is discovered, added devices might need maintenance. Mistakes are classified by seriousness( Safety and security, Stability, House cleaning ), making certain that immediate problems are examined and resolved quickly to reduce any type of effect on safety and security or operations. The EEHA database should track and tape-record the lifecycle of faults in addition to the corrective actions taken. Applying a robust Risk-Based Evaluation( RBI )method is critical for guaranteeing conformity and security in taking care of Electric Tools in Hazardous Areas( EEHA). Automated Mistake Scoring and Lifecycle Administration: Effortlessly handle faults and track their lifecycle to enhance examination accuracy. The introduction of this support for risk-based evaluation further enhances Inspectivity's setting as a best-in-class service for regulatory compliance, as well as for any asset-centric assessment use situation. If you are interested in discovering more, we invite you to request a demonstration and find how our solution can transform your EEHA management procedures.

With over one decade of combined Ex-spouse experience (IECEx/ATEX, EEHA), Saipex began to promote the importance of skills of all personnel involved in the Hazardous Area area in 2019. In 2021, our partnership with IndEx and Tech Skill International (TSI) noted a landmark in the Saipex road to continue Ex lover improvement.

Indicators on Roar Solutions You Should Know

In regards to eruptive risk, a dangerous location is an atmosphere in which an eruptive atmosphere is present (or might be anticipated to be present) in amounts that require special safety measures for the construction, installment and usage of equipment. In this post we discover the challenges faced in the office, the risk control actions, and the required proficiencies to work securely.

(https://www.indiegogo.com/individuals/38463782)

It issues of modern life that we make, keep or handle a variety of gases or liquids that are deemed flammable, and a variety of dirts that are deemed flammable. Roar Solutions. These materials can, in certain conditions, develop eruptive atmospheres and these can have major and unfortunate effects. The majority of us recognize with the fire triangular eliminate any type of one of the 3 aspects and the fire can not take place, however what does this mean in the context of harmful locations? When breaking this down right into its most basic terms it is essentially: a mix of a certain amount of launch or leak of a certain substance or product, combining with ambient oxygen, and the existence of a resource of ignition.

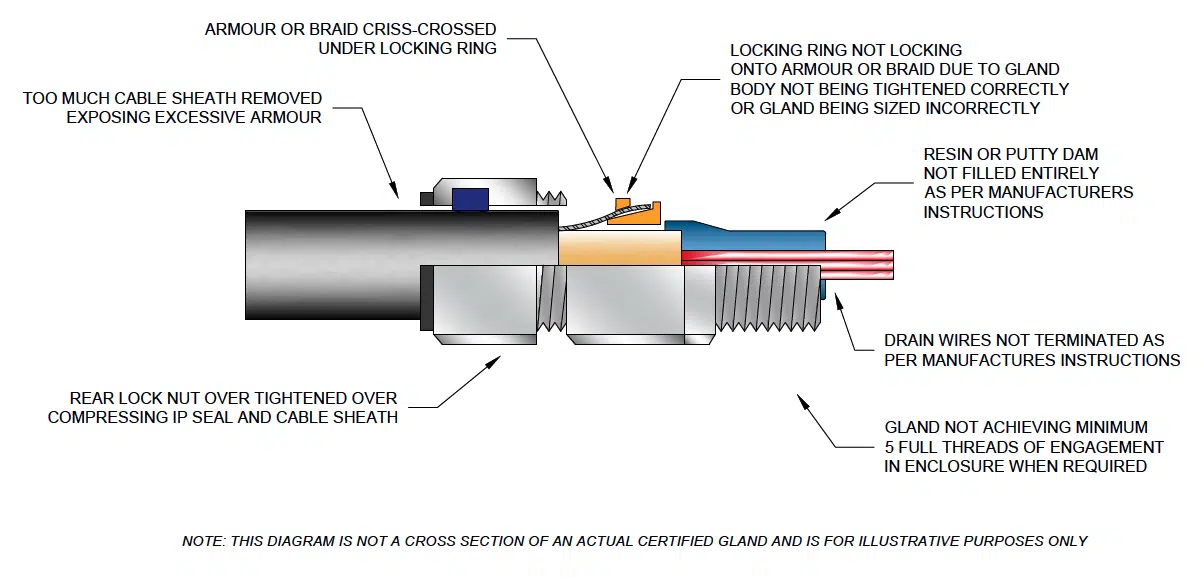

This is then verified through evaluation and testing and is preserved throughout the life of the installation by using the appropriate upkeep strategies, supplemented by periodic assessment. When all these measures are taken, they should also be documented. The confirmation file includes details such as the dangerous location category illustration, manufacturers' paperwork, devices qualification, style illustrations and estimations, evaluation records, and documents of an individual's competency and continuing expert development (CPD), such as through ECA's eCOMS software program.

Little Known Facts About Roar Solutions.

It is essential that pupils understand and have a complete knowledge regarding what exactly makes up an unsafe location. The trainee must additionally know why training is essential prior to trying to take on work or defining devices right into an unsafe location. These areas are additionally called categorized locations and are specified as locations which have a high probability of a surge due to the fact that of the possible presence of flammable gases, vapors, dusts and so on.

Industries which contain dangerous link areas are now requiring that electrical employees that are defining or operating in these areas must have an unsafe area credentials that deems them qualified. Jobs in these industries are very fulfilling so you require to be prepared. To fulfill this need for the industry, across the country acknowledged training in Certification IV in Hazardous location Electric and EEHA training on the development of knowledgeable specialists.

The Buzz on Roar Solutions

Technology Abilities Australia is a Registered Training Organization offering you with the most budget friendly and quickest way in acquiring your qualification - eeha training. Our teachers are market qualified and have a number of years of process experience. Our programs have assisted numerous people from business managers to everyday employees in obtaining a solid hang on this not so complicated but high risk training

The training also consists of recognizing the harmful locations, resources of surge and the properties of dangerous materials in addition to the obligations and functions of all events, laws, systems, requirements and method codes linked to harmful locations. We offer instrumentation and harmful area solutions that remain in conformity to most current AS/NZS and global industry requirements.

Report this page